- HOME

- Products

- Package product

- Application of Sodium Hypochlorite Generator in Water Plants

Microbial control in water systems is achieved primarily through continuous or intermittent sanitization procedures.In recent years, the installation of sodium hypochlorite generator in the water plant, the on-site preparation of sodium hypochlorite solution, adding to the water for disinfection is becoming more and more common, and is becoming a global trend, the sodium hypochlorite generator produced by our company, for independent research and development, stable operation, almost maintenance-free, low cost advantages have been exported to more than 20 countries and regions around the world.

Effective chlorine production: 50-400000g/H

Effective chlorine concentration: 3-10g/L

Installed power: 0.3-90KW

Host size: customized

Delivery cycle: 25 days

WhatsApp:+86 19953182842

Email: henry@hoclshine.com

Product Details

Due to the high risk of using chlorine for disinfection. If the chemical raw materials that produce hypochlorite are not properly disposed of, the raw materials can cause fires, explosions, and even casualties during storage and transportation. Chlorine itself is also highly toxic, and its storage, transportation, and use are also quite dangerous. Therefore, in order to avoid the aforementioned risks, chlorine disinfection has been continuously decreasing.

Product parameter

Effective chlorine production: 50-400000g/H

Effective chlorine concentration: 3-10g/L

Installed power: 0.3-90KW

Host size: customized

Delivery cycle: 25 days

WhatsApp:+86 19953182842

Email: henry@hoclshine.com

Product advantage

In 1998, the Disinfection System Committee of the Water Quality Branch of the American Water Industry Association conducted a survey on the disinfection status of large and medium-sized tap water in the United States, which showed that the number of water plants using chlorine gas disinfection had increased from 91% in 1978 to 83.8% in 1998. The survey on the disinfection status of small water plants also showed that only 61% of the surveyed water plants used chlorine gas as their water source. On the contrary, the technology of on-site preparation of disinfectants is gradually being developed and utilized, and electrolysis is one of the main methods for on-site preparation of disinfectants. As a result, the sodium hypochlorite generator that utilizes the principle of chemical electrolysis to manufacture sodium hypochlorite disinfectants on disinfection sites has also been increasingly widely used.

The sodium hypochlorite generator was introduced for drinking water disinfection as early as the early 1970s, but due to the cheap price of chlorine gas and loose drinking water regulations in the United States at that time, the generator was not widely used. Nowadays, with the increasingly strict regulations on drinking water and the continuous increase in chlorine gas prices, and the fact that the sodium chlorate generator has been proven to be an effective disinfection method, it has been increasingly widely used in the United States. By 2002, more than 1500 water plants in the United States had switched from using chlorine gas for disinfection to using sodium hypochlorite on-site generation devices for water plant disinfection. Meanwhile, Hubert Fleming and Mayne Huebner also pointed out that due to climate reasons, sodium hypochlorite generators are more commonly used in southern states of the United States.

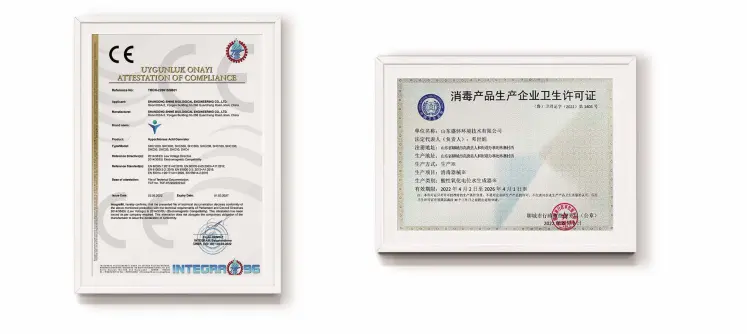

Qualification certificate

Submitted successfully

We will contact you as soon as possible