- HOME

- Products

- Package product

- The importance of safe production of sodium hypochlorite generator

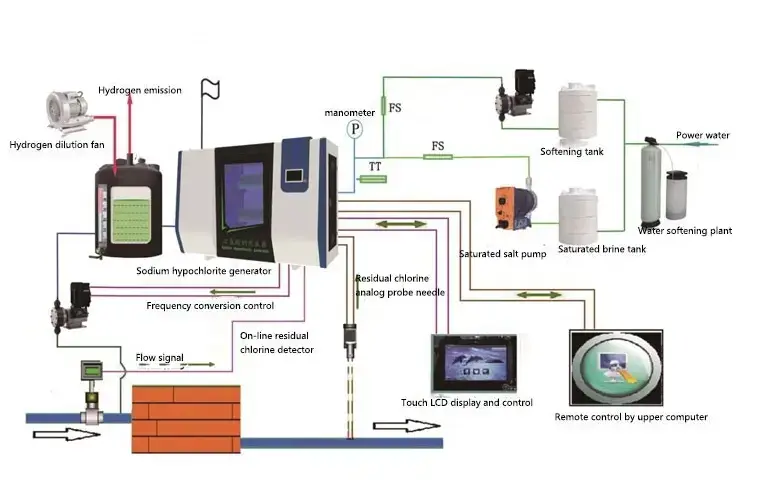

The sodium hypochlorite generator is the primary consideration in design, therefore, in terms of equipment

structure and automation control, safety risks should be minimized to meet or exceed national requirements.

Effective chlorine production: 50-40000g/H

Effective chlorine concentration: 3-130g/L

Installed power: 0.3-90KW

Host size: customized

Delivery cycle: 25 days

WhatsApp:+86 19953182842

Email: henry@hoclshine.com

Product Details

The raw materials required for the electrolysis method sodium hypochlorite generator do not contain any hazardous chemicals,

and the indicators of each link show that no adverse safety factors have occurred. The effective chlorine concentration of the

sodium hypochlorite solution produced is 0.3% to 0.8%, which is far lower than the national requirement of 5%. The sodium

hypochlorite generator is a device with low operating costs, accurate drug dosing, and excellent disinfection effects. The sodium

hypochlorite solution produced on site belongs to a low toxicity, low cost, efficient, and safe chlorine containing disinfection method.

Therefore, the sodium hypochlorite generator should be the safest and most effective disinfection process in the field of water quality disinfection.

Product parameter

effective chlorine production: 50-40000g/H

Effective chlorine concentration: 3-130g/L

Installed power: 0.3-90KW

Host size: customized

Delivery cycle: 25 days

WhatsApp:+86 19953182842

Email: henry@hoclshine.com

Product advantage

Raw material safety: The electrolytic sodium hypochlorite generator uses electrolytic salt solution to obtain the finished product - sodium hypochlorite solution.

Users only need to have a power supply and easily available salt to prepare. The salt market has sufficient supply and is a necessity for daily life. It is not restricted

for purchase, let alone prohibited items. Storage and stacking are not affected by the environment.

Equipment structure: Setting up an inter pole hydrogen separator can effectively and timely release the hydrogen generated during electrolysis. When electrolyzing

salt water, hydrogen gas is generated at the cathode. According to theoretical data, 350 liters of hydrogen gas are generated for every 1kg of effective chlorine

produced. As hydrogen gas is insoluble in water, its flow in the electrolytic cell greatly affects the electrolysis efficiency. At the same time, failure to discharge

hydrogen gas in a timely manner can increase the pressure inside the electrolytic cell, posing a safety hazard. Therefore, we set up a hydrogen separation device

on the electrode to timely discharge the hydrogen gas generated during electrolysis. Reduce the harm to zero.

Electrical safety: The electrolytic sodium hypochlorite generator uses low voltage direct current, and the rectifier power output is a safe voltage. The electric control

cabinet is equipped with grounding devices, and copper bars or cable connections are equipped with insulation protection devices to avoid human contact.

Hydrogen discharge from the storage tank: The system adopts three times of hydrogen discharge. The sodium hypochlorite solution generated by electrolysis flows

into the storage tank through a pipeline, and a high airflow fan is installed at the upper end of the storage tank. Its purpose is to remove the remaining hydrogen

gas in the storage tank three times through strong blowing. All discharged hydrogen gas shall be combined into the hydrogen discharge pipeline and led to outdoor

heights, and flame retardant and lightning protection measures shall be taken. Dilute the hydrogen concentration at the high-altitude hydrogen discharge

outlet to 0.5% (volume ratio)

Hydrogen detection device: A hydrogen detection device is installed at a high place in the equipment room, with a concentration setting of 0.25%. If the concentration

exceeds the set value, an alarm device will be triggered, and the indoor fan can be started to exhaust air and stop the system operation.

No irritating odor overflow in the equipment room: The sodium hypochlorite solution storage tank is a closed container, with an outlet pipe set at the upper end leading

to the outdoor area. The two fans are standby for each other, and the air pressure switch is used to detect the air volume and switch at any time, with an alarm output.

Qualification certificate

Customer negotiation

Submitted successfully

We will contact you as soon as possible