- HOME

- Products

- Sodium Hypochlorite Generator

- Precautions for disinfection of sodium hypochlorite generator in water treatment plants

Attention should be paid to the daily maintenance and upkeep of equipment in the disinfection of sodium hypochlorite generators in water plants

Effective chlorine production: 50-15000g/H

Effective chlorine concentration: 3-10g/L

Installed power: 0.3-90KW

Host size: Customized delivery cycle: 25 days

WhatsApp:+86 19953182842

Email: henry@hoclshine.com

Product Details

Less odor: Under the same effective chlorine dosage, the odor of sodium hypochlorite is significantly reduced compared to

lvqi, reducing the common "chlorine odor". Better taste: Sodium hypochlorite is alkaline, effectively improving the taste of the

factory water. Pipeline rust prevention: The alkaline property of sodium hypochlorite can effectively reduce pipeline rust,

improve the service and operation life of the pipeline. Water quality safety: The product of the sodium hypochlorite generator

is pure and does not produce any other by-products, making it safer.

Product parameter

Effective chlorine production: 50-15000g/H

Effective chlorine concentration: 3-10g/L

Installed power: 0.3-90KW

Host size: Customized delivery cycle: 25 days

WhatsApp:+86 19953182842

Email: henry@hoclshine.com

Product advantage

-The flow control valve, raw material pipeline, and water jet are prone to blockage when the raw materials contain impurities.

Attention should be paid to cleaning and unblocking, and sediment in the raw material tank should be regularly cleaned.

-The equipment casing is made of PVC plastic, and collision, squeezing, and exposure to sunlight are prohibited.

-The raw materials used in the equipment should be stored separately and strictly prohibited from being stored together

with flammable materials such as wood chips, sulfur, phosphorus, etc. It is strictly prohibited to compress or collide.

-In winter, attention should be paid to antifreeze and necessary heating measures should be taken indoors to avoid damaging

equipment. The equipment room should be dry, dark, and well ventilated.

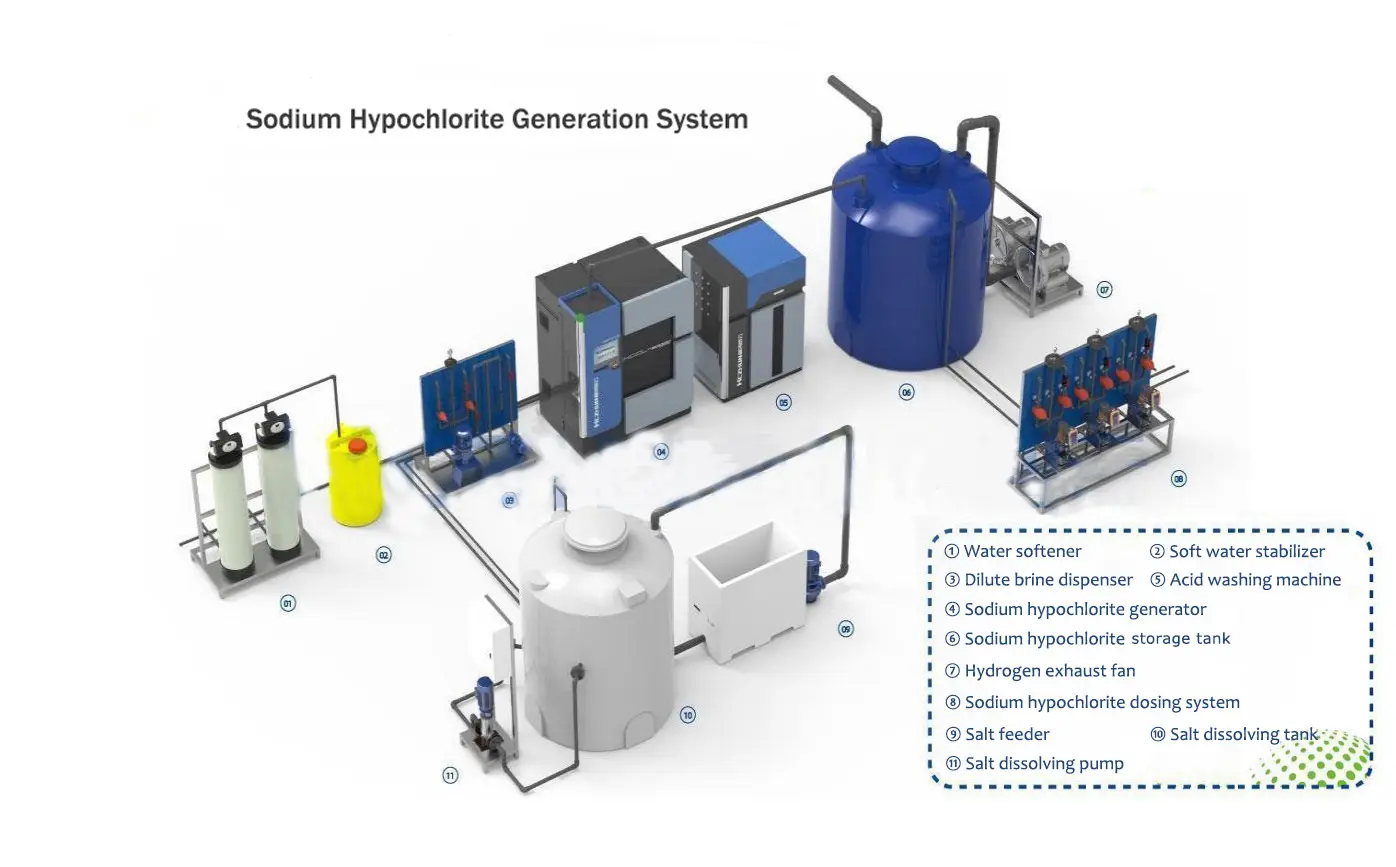

Process Flow Diagram

Qualification certificate

Application

Submitted successfully

We will contact you as soon as possible