- HOME

- Products

- Sodium Hypochlorite Generator

- Safe hydrogen removal from sodium hypochlorite generator with conventional effective chlorine concentration (0.3% -1%)

The sodium hypochlorite generator with conventional effective chlorine concentration is equipped with

a three-stage hydrogen removal system.

Effective chlorine production: 50-400000g/H

Effective chlorine concentration: 3-130g/L

Installed power: 0.3-90KW

Host size: customized

Delivery cycle: 25 days

WhatsApp:+86 19953182842

Email: henry@hoclshine.com

Product Details

The sodium hypochlorite generator generates hydrogen and a small amount of chlorine gas during the electrolysis reaction.

The hydrogen discharge pipeline and hydrogen exhaust fan safely handle hydrogen gas, and a small amount of chlorine gas is

directly dissolved in soft water, which is very safe.

Product parameter

Effective chlorine production: 50-400000g/H

Effective chlorine concentration: 3-130g/L

Installed power: 0.3-90KW

Host size: customized

Delivery cycle: 25 days

WhatsApp:+86 19953182842

Email: henry@hoclshine.com

Product advantage

Hydrogen discharge from the storage tank: The system adopts three times of hydrogen discharge. The sodium hypochlorite solution generated

by electrolysis flows into the storage tank through a pipeline, and a high airflow fan is installed at the upper end of the storage tank. Its purpose

is to remove the remaining hydrogen gas in the storage tank three times through strong blowing. All discharged hydrogen gas shall be combined

into the hydrogen discharge pipeline and led to outdoor heights, and flame retardant and lightning protection measures shall be taken. Dilute the

hydrogen concentration at the high-altitude hydrogen discharge outlet to 0.5% by volume.

Hydrogen detection device: A hydrogen detection device is installed at a high place in the equipment room, with a concentration setting of 0.25%.

If the concentration exceeds the set value, an alarm device will be triggered, and the indoor fan can be started to exhaust air and stop the system operation.

No irritating odor overflow in the equipment room: The sodium hypochlorite solution storage tank is a closed container, with an outlet pipe set at

the upper end leading to the outdoor area. The two fans are standby for each other, and the air pressure switch is used to detect the air volume

and switch at any time, and an alarm output is given.

4.The raw materials required for the electrolysis method sodium hypochlorite generator do not contain any hazardous chemicals, and the indicators of

each link show that no adverse safety factors have occurred. The effective chlorine concentration of the sodium hypochlorite solution produced is 0.3% to 0.8%,

which is far lower than the national requirement of 5%. The sodium hypochlorite generator is a device with low operating costs, accurate drug dosing, and

excellent disinfection effects. The sodium hypochlorite solution produced on site belongs to a low toxicity, low cost, efficient, and safe chlorine containing

disinfection method. Therefore, the sodium hypochlorite generator should be the safest and most effective disinfection process in the field of water quality disinfection.

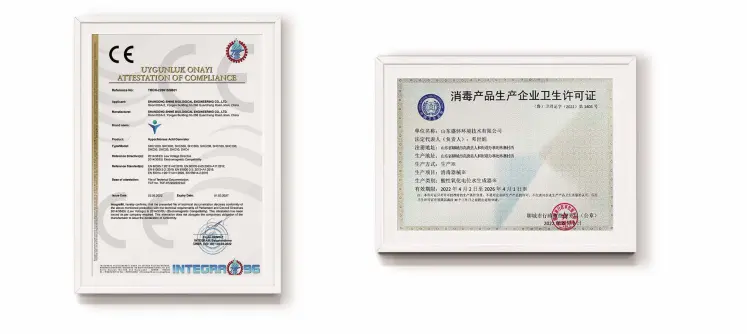

Qualification certificate

Submitted successfully

We will contact you as soon as possible