- HOME

- Products

- Sodium Hypochlorite Generator

- Sales of sodium hypochlorite generator factory

The image equipment is a real-life image sent to a customer in Uganda, and the product adopts a preprocessing system with a delivery period of 15 days and includes a dosing pump. The original PLC of the product uses Siemens brand, highly integrated; The quality has reached export inspection free quality. The pump uses Grundfos from the United States, and the electrolytic cell uses a Dutch brand.

Model:SHC-2000

Effective chlorine yield:2000g/h

Effective chlorine concentration:8-10g/L

Installed power:12kw

Host size:1300*700*1800

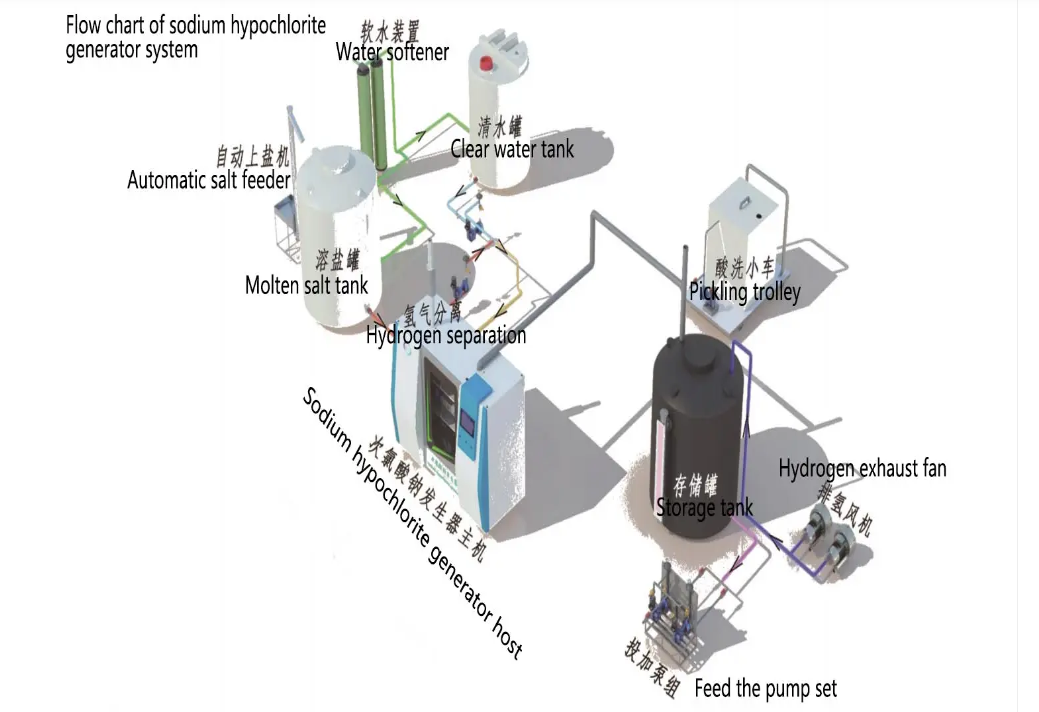

Sodium chloride solution under the action of a certain electrode, a series of electrochemical reactions occurred in the electrolytic cell to generate sodium hypochlorite solution, the chemical reaction process can be summarized as follows,Because the molecular weight of Naclo is 1.05 times that of CL2, and the charge transfer number of each NacLo molecule is the same as that of CL2 molecule during oxidation reaction, each gram of NACIO generated during the production of sodium hypochlorite through electrochemical reaction is equivalent to 0.952 grams of

Product parameter

*Model:SHC-2000

*Effective chlorine yield:2000g/h

*Effective chlorine concentration:8-10g/L

*Installed power:12kw

*Host size:1300*700*1800

Product advantage

*The entire product adopts patented design, reducing floor space, high integration, and simple and fast installation, operation, and maintenance.

*The salt dissolving system is a uniform brine concentration storage tank with backwashing function, which has good salt dissolving effect, low energy consumption, automatic backwashing to reduce crystallization and extend service life.

*The core component electrodes of the generator, both positive and negative, are made of pure titanium as the substrate, and the electrode has a service life of more than 10 years.

*The "Electrode Pushing Flow Device" developed with unique patented technology inside the electrolytic cell ensures the safe, efficient, and stable electrolysis reaction by providing step-by-step flow of electrolyte according to the equipment output and concentration requirements.*The hydrogen discharge system of the generator adopts the patented technology of "three-level safety hydrogen discharge device", which conducts hydrogen discharge and dilution during electrolysis, storage, infusion pipelines, and other processes, ensuring the safety and reliability of the entire system.

*The entire system has a high degree of automation and is subject to multi-level safety monitoring. It monitors the entire process of current, voltage, temperature, pressure, flow, and output during operation, automatically adjusting to ensure the safe operation of the equipment

Submitted successfully

We will contact you as soon as possible