- HOME

- Products

- Sodium Hypochlorite Generator

- Small integrated sodium hypochlorite generator

Sodium hypochlorite generator is a device used for on-site production of sodium hypochlorite solution. Sodium hypochlorite solution is a powerful disinfectant and oxidant, commonly used in water treatment, sanitation, and industrial applications. This generator utilizes the electrolysis process to convert salt and water into sodium hypochlorite.

Effective chlorine production: 50-400000g/H

Effective chlorine concentration: 3-10g/L

Installed power: 0.3-90KW

Host size: customized

Delivery cycle: 25 days

WhatsApp:+86 19953182842

Product Details

The integrated sodium hypochlorite generator is a high-tech equipment independently developed by our company with proprietary technology. It can serve places such as midway booster pump stations, hospital sewage, rural drinking water, animal husbandry, landscape water, swimming pools, and secondary water supply tanks for disinfection and sterilization.

This device uses SHINE's proprietary technology electrodes to achieve superior salt water electrolysis efficiency and energy-saving effects. The SHINE system has been successfully running both domestically and internationally for many years, and its security and superiority have been increasingly recognized by customers.

Detailed parameters

Chlorine production | Effective chlorine production

| Power supply | Water supply | Raw material |

0.1kg/h-1kg/h | 7000-9000ppm | 220V,single | water pressure2-3bar | Iodine free refined salt |

Product advantage

1、Standardized configuration: The main equipment adopts standardized installation and has been installed and debugged before leaving the factory. Flexible arrangement of supporting equipment;

2、Reasonable design: not limited by the width of on-site doors, the width of ordinary household doors is sufficient. Reliable selection of electrical components;

3、Easy installation and debugging: All pipelines and electrical systems have been assembled and debugged before leaving the factory, and installation and debugging work can be completed with online guidance;

4、The cost-effectiveness advantage is obvious: through reasonable design and product selection, while ensuring the safe operation of the system, various costs are reduced, and the cost-effectiveness is high.

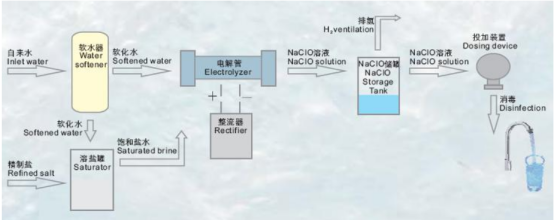

Equipment flow diagram

The equipment consists of an inlet module, a salt dissolution module, a generation module, a storage and hydrogen release module, a dosing module, and a control module.

Qualification certificate

Application scenarios

Submitted successfully

We will contact you as soon as possible