- HOME

- Products

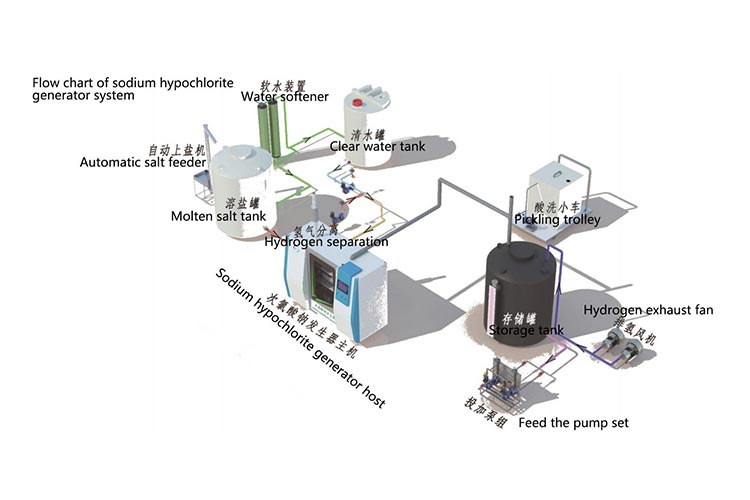

- Sodium Hypochlorite Generator

- Sodium hypochlorite water treatment equipment

Sodium hypochlorite generator is a kind of equipment for disinfection and sterilization of water treatment. The equipment uses salt and water as raw materials to produce sodium hypochlorite solution through electrolytic reaction

AC power consumption:4.5Kw.h/kg

Salt consumption:3.2kg/kg

Production electricity:0.75RMB

Available chlorine content:0.7%-1%

The whole system is equipped with a three-stage hydrogen shooting technology device, the cathode discharged hydrogen during the electrolytic cell electrolysis process, and the hydrogen separator above it can effectively separate the gas and liquid, and timely discharge the hydrogen generated in the electrolytic cell during the electrolytic process. In addition, the storage tank is equipped with a hydrogen fan to dilute the hydrogen concentration to less than 0.5% and discharge it to the outside. The exhaust pipe is equipped with a wind pressure switch for three-level protection.

Product parameter

AC power consumption:4.5Kw.h/kg

Salt consumption:3.2kg/kg

Production electricity:0.75RMB

Available chlorine content:0.7%-1%

Product advabtage

1: The system is equipped with three-stage hydrogen patting technology. In addition to the hydrogen separator, which can separate 60%-70% of the hydrogen in the system, it is equipped with a two-stage hydrogen patting channel to gradually discharge the remaining hydrogen through the electrolytic cell liquid out stage and storage stage, and is diluted to less than 0.5% by the hydrogen patting fan, and then safely discharged

2: The system adopts a brine ratio device that automatically calibrates the flow rate to monitor and control the brine ratio concentration in real time, ensure the brine precision ratio, reduce energy consumption, and improve stability and conversion rate

3: The system adopts multi-polarization safety monitoring system to monitor flow, temperature, pressure, current and voltage, liquid level, residual chlorine, hydrogen and other control points for multi-polarization, and carry out internal chain, prompt alarm information after failure, and carry out safety chain shutdown and other functions.

4: Internet of Things technology, the PLC in the system can upload all control points of the PLC system to the cloud platform through the Internet of Things card, and customers can query, detect and control through the mobile APP or the PC side of the computer, and grasp the field operation in real time.

Submitted successfully

We will contact you as soon as possible