- HOME

- Products

- Sodium Hypochlorite Generator

- Sodium hypochlorite generator Professional installation

The SHC sodium hypochlorite generator is installed under the guidance of professional engineers.

Effective chlorine production: 50-15000g/H

Effective chlorine concentration: 4-10g/L

Installed power: 0.3-90KW

Host size: customized

Delivery cycle: 25 days

WhatsApp:+8619953182842

Email: henry@hoclshine.com

When using a sodium hypochlorite generator, the following precautions should be taken to ensure the safety and effectiveness of the operation

Product parameter

-Protective measures: Before operating the sodium hypochlorite generator, be sure to wear appropriate personal protective equipment, including chemical goggles, protective gloves, and laboratory jackets. Avoid contact with skin, eyes, or mouth with sodium hypochlorite.

-Ventilation: Ensure that the operation is carried out in a well ventilated laboratory environment. The hydrogen gas and sodium hypochlorite vapor generated during the electrolysis process need to be properly discharged to avoid their accumulation and potential hazards.

-Avoid sources of ignition: Sodium hypochlorite is an oxidant that should be avoided from contact with open flames or other sources of ignition during operation to prevent fires or explosions.

-Current control: Reasonably control the strength of the current during the electrolysis process according to the needs and equipment capabilities, in order to control the production of sodium hypochlorite.

-Accurate measurement: When preparing a saline solution, ensure accurate weighing of sodium chloride and water to obtain the required concentration of sodium hypochlorite.

-Cleaning the electrolytic cell: After each use, clean the electrolytic cell in a timely manner to prevent the accumulation of residual sodium hypochlorite and cross contamination.

-Storage of sodium hypochlorite: If sodium hypochlorite solution needs to be stored, please store it in a sealed container labeled with a chemical label, away from organic matter and reducing agents. Avoid mixing with acidic substances to avoid the generation of toxic chlorine gas.

Qualification certificate

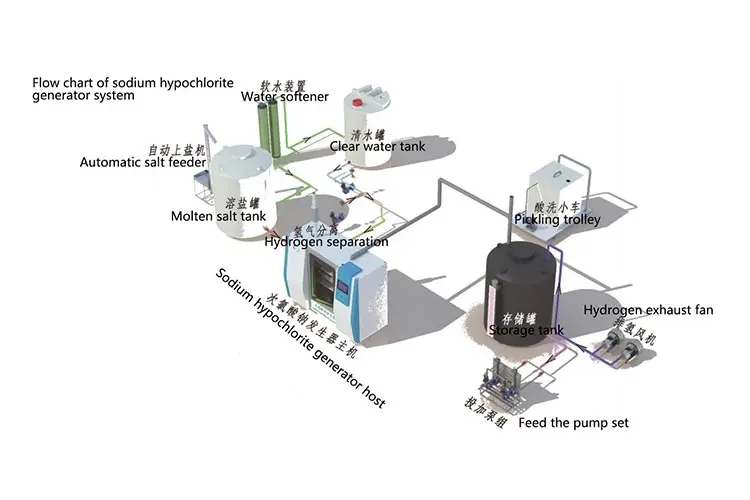

Process Flow Diagram

Application scenarios

Submitted successfully

We will contact you as soon as possible