- HOME

- Products

- Sodium Hypochlorite Generator

- Sodium hypochlorite generator optimize water quality

The disinfection effect of sodium hypochlorite generator plays a good role in optimizing water quality.

Effective chlorine production: 50-15000g/H

Effective chlorine concentration: 4- 8g/L

Installed power: 0.3-90KW

Host size: 700 * 450 * 900

Delivery cycle: 25 days

WhatsApp:+8619953182842

Email: henry@hoclshine.com

Chlorine can be used as a pure gas, solid in the form of calcium hypochlorite, or liquid in the form of sodium hypochlorite. The use of an on-site sodium hypochlorite generation system to manufacture sodium hypochlorite in facilities is an inexpensive, simple, and effective method for providing chlorine for disinfection.

Product parameter

Effective chlorine production: 50-15000g/H

Effective chlorine concentration: 4- 8g/L

Installed power: 0.3-90KW

Host size: 700 * 450 * 900

Delivery cycle: 25 days

WhatsApp:+8619953182842

Email: henry@hoclshine.com

Product advantage

-Safer: The concentration range of sodium hypochlorite solution generated by the on-site electrochlorination system is between 0.4% -0.8%, with a pH value less than 10; This solution is considered a non hazardous chemical. Therefore, this solution will not pose a threat to public safety, nor will it require the development of a comprehensive risk management plan for its handling and use. The hydrogen gas generated as a byproduct during the electrolysis process is safely contained, rapidly diluted, and carefully discharged into the atmosphere. Another safety feature is that on-site electrochlorination eliminates the storage and transportation of hazardous chemicals.

-Low cost: The cost of producing chlorine gas using on-site electrochlorination systems is usually much lower than the cost of purchasing an equal amount of

chlorine gas in the form of bulk sodium hypochlorite.

-Reduce the formation of chlorine by-products: Bulk sodium hypochlorite will decompose during storage, leading to the formation of chlorine disinfection

by-products such as chlorates. On the contrary, sodium hypochlorite produced by on-site electrochlorination systems is typically measured within a few hours

of production, significantly reducing degradation and the formation of chlorine by-products. Due to the low efficiency of electrochemical reactions, some

chlorates are also produced as by-products during the electrochlorination process. However, Dinola scientists and engineers have been studying this aspect

of the process for over a decade and have developed a patent pending solution that can minimize the formation of chlorates during the electrolysis process.-More sustainable: Due to significantly reducing waste, reducing the threat of transporting and storing bulk concentrated chlorine to health and environmental

safety, reducing the formation of by-products, and minimizing carbon dioxide footprint, on-site electrochlorination is the most sustainable practice for water

disinfection.

-More reliable: By producing sodium hypochlorite and chlorine gas on their own, factories no longer rely on purchasing chemical products from the market,

which are more susceptible to price fluctuations, depletion, and delivery delays than water, salt, and electricity.

Application Display

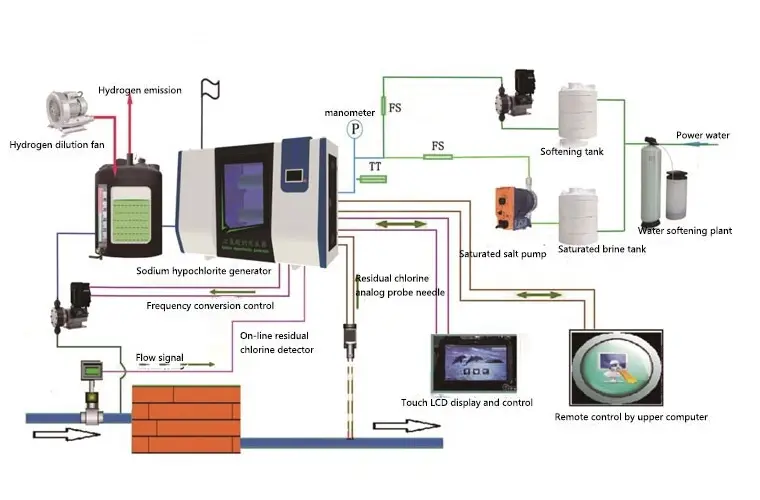

Process Flow Diagram

Qualification certificate

Customer negotiation

Submitted successfully

We will contact you as soon as possible