- HOME

- Products

- Sodium Hypochlorite Generator

- Sodium hypochlorite generator for seawater desalination

Desalination of seawater refers to the removal of salt and impurities from seawater, making it fresh water that can be consumed or used for agricultural irrigation. Seawater desalination equipment is a key tool to achieve this goal.

Effective chlorine production: 50-15000g/H

Effective chlorine concentration: 3-10g/L

Installed power: 0.3-90KW

Host size: customized

Delivery cycle: 25 days

WhatsApp:+8619953182842

Email: henry@hoclshine.com

Product Details

1. Distillation is one of the earlier seawater desalination technologies, which mainly utilizes the characteristic that the boiling point of water is lower than that of saltwater. It evaporates seawater by heating it, and then condenses the steam into fresh water. The distillation method usually includes two methods: multi-stage distillation and flash distillation.

(1) Multi stage distillation refers to the process of dividing seawater into multiple parts, each of which undergoes evaporation and condensation under different temperature and pressure conditions to gradually remove salt and impurities. The advantage of this method is that it can produce high-purity fresh water, but it requires higher energy consumption.

(2) Flash evaporation refers to heating seawater to a temperature higher than its boiling point, then rapidly reducing pressure, causing seawater to instantly evaporate and condense into fresh water. The advantage of this method is that it can process a large amount of seawater in a short period of time, but the purity of freshwater is lower.

2. The reverse osmosis method of seawater desalination equipment is currently a widely used seawater desalination technology. Its working principle is to use a semi permeable membrane to forcibly reverse osmosis the water in seawater by applying high pressure, leaving salt and impurities on one side of the membrane, while pure water enters the other side through the pores of the membrane. Reverse osmosis usually includes three steps: pretreatment, reverse osmosis, and post-treatment.

(1) Pre treatment refers to the pre-treatment of seawater to remove impurities such as suspended solids, organic matter, and microorganisms, in order to protect the normal operation of reverse osmosis membranes. Common pretreatment methods include filtration, sedimentation, and disinfection.

(2) Reverse osmosis refers to the process of applying high pressure through a reverse osmosis membrane to preprocessed seawater, allowing water to reverse permeate and retain salt and impurities on one side of the membrane. Reverse osmosis membranes are typically composed of multiple layers of thin films, including nanofiltration membranes with smaller pore sizes and reverse osmosis membranes with smaller pore sizes.

(3) Post treatment refers to the further treatment of fresh water generated by reverse osmosis membranes to adjust their pH and mineral content to meet the standards for drinking or irrigation water. Common post-processing methods include carbon filtration, disinfection, and mineralization.

Overall, seawater desalination equipment removes salt and impurities from seawater through distillation or reverse osmosis, resulting in fresh water. The working principle of these devices is based on physical and chemical principles, achieving the separation and purification of seawater through heating, pressure, and semi permeable membranes.

Application Display

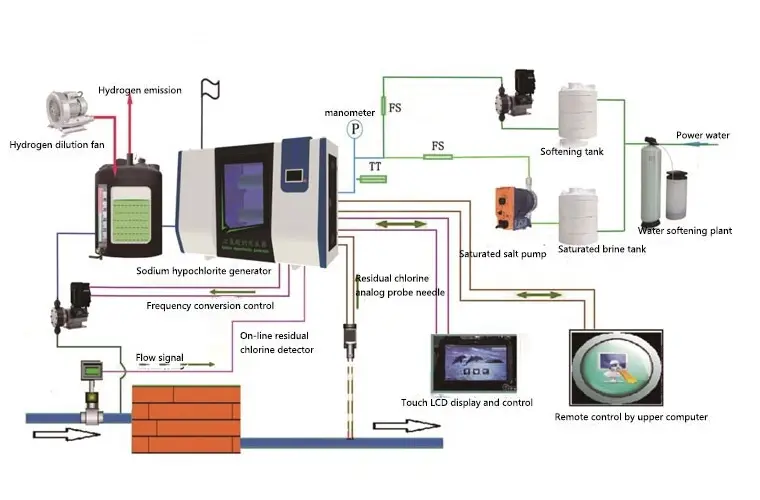

Process Flow Diagram

Qualification certificate

Customer negotiation

Submitted successfully

We will contact you as soon as possible