- HOME

- Products

- Sodium Hypochlorite Generator

- Sodium hypochlorite generator descaling maintenance

The sodium hypochlorite generator produces some by-products during operation, so regular descaling and

maintenance are required.

Effective chlorine production: 50-15000g/H

Effective chlorine concentration: 3-10g/L

Installed power: 0.3-90KW

Host size: customizedDelivery cycle: 25 days

WhatsApp:+8619953182842

Email: henry@hoclshine.com

Product Details

During the electrolysis process of the sodium hypochlorite generator, compounds of magnesium and calcium ions will gradually deposit on the electrode wall, forming scale (the deposition rate is related to the hardness of the local water quality). The formation of scale can lead to a decrease in electrolysis efficiency, and when scale is severe, it can clog the inside of the electrode and affect its use. At this point, the electrodes of the sodium hypochlorite generator should be cleaned. The electrode cleaning machine is an ideal equipment for cleaning scale inside the electrodes of sodium hypochlorite generators.

Product parameter

Effective chlorine production: 50-15000g/H

Effective chlorine concentration: 3-10g/L

Installed power: 0.3-90KW

Host size: customizedDelivery cycle: 25 days

WhatsApp:+8619953182842

Email: henry@hoclshine.com

Product advantage

When cleaning the electrodes, the flow meter adjustment valve should be closed, the valve leading to the storage tank should be closed, the upper and lower valves of the brine tank should be closed, and the discharge valve on the cleaning machine should be closed.

Connect the water supply pipe (water pump outlet) of the cleaning machine to the cleaning port of the electrode, and connect the return water port (outlet above the cleaning machine) of the cleaning machine to another cleaning port of the electrode.

Two or four electrodes can be cleaned together when cleaning. Recommend cleaning two electrodes together and then cleaning the other two.

Open the two valves connecting the cleaning machine pipeline and the water supply valve on the cleaning machine.

Prepare hydrochloric acid cleaning solution at 10:1, which is 10 parts of water and 1 part of hydrochloric acid (hydrochloric acid concentration greater than 30%). Approximately 35-40 cleaning solutions need to be prepared.

Open doors, windows or exhaust fans.

Confirm that the valves in the cleaning pipeline are not closed, and turn on the water pump.

There will be a large number of bubbles discharged from the return water pipe of the cleaning machine. During the cleaning process, the bubbles will gradually decrease, and then decrease to a small amount. At this time, add 500-1000ml of hydrochloric acid. If there are bubbles discharged from the return water pipeline of the cleaning machine, it indicates that it has not been cleaned thoroughly. Continue to clean and add hydrochloric acid. Until only a small amount of bubbles are expelled.

If a decrease in cleaning solution is found during the cleaning process, the pump should be stopped in a timely manner to check for any leakage.

Remember not to use concentrated hydrochloric acid to clean the electrodes.

After cleaning, restore all valves to their original state and drain any residual liquid from the cleaning machine.

Open the valve under the electrode to empty the cleaning solution inside the electrode, and turn on the salt water pump to clean the hydrochloric acid inside the electrode with salt water.

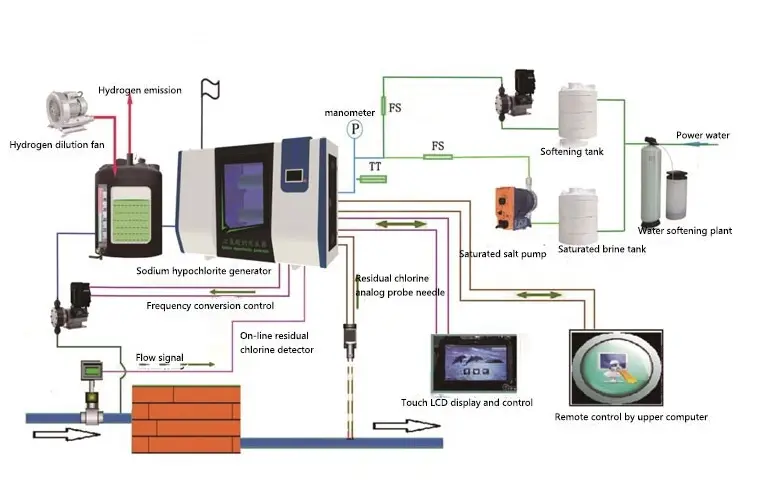

Process Flow Diagram

Qualification certificate

Customer negotiation

Application Display

Submitted successfully

We will contact you as soon as possible