- HOME

- Products

- Sodium Hypochlorite Generator

- Sodium hypochlorite generator for aquiculture

The sodium hypochlorite generator has become an ideal choice for aquaculture operators to disinfect water bodies due to its high efficiency, safety, and environmental friendliness.

Effective chlorine production: 50-600000g/H

Effective chlorine concentration: 3-10g/L

Installed power: 0.3-90KW

Host size: Customized delivery cycle: 7-25 days

WhatsApp: +86 19953182842

Email: henry@hoclshine.com

Product Details

In shrimp ponds, the seawater introduced into the sea carries various protozoa such as fish, crustaceans, harmful bacteria,

and viruses. Fish are natural enemies of shrimp, and bacteria and viruses can cause diseases on shrimp. In addition to competing

for food, crustaceans are also carriers of shrimp viruses. Therefore, before releasing shrimp fry, it is necessary to thoroughly kill

the fish, crustaceans, protozoa, bacteria, and viruses in the pond. After releasing shrimp fry and raising them for a period of

time, the accumulation of shrimp excrement and bait residue can deteriorate the bottom quality of the pond, leading to the

growth of bacteria and viruses; The seawater entering during the process of adding and changing water will also be

reintroduced with bacteria and viruses. Therefore, during the aquaculture period, the aquaculture water should also be

regularly or irregularly disinfected to eliminate bacteria, viruses, and protozoa in the water. This is the purpose of cleaning

the pond before releasing shrimp seedlings and disinfecting the water during the aquaculture period.

Product parameter

| Effective chlorine production | 50-60000g/h |

| Effective chlorine concentration | 3-10g/L |

| Installed power | 0.3-90KW |

| Host size: Customized delivery cycle | 7-25 days |

| +86 19953182842 | |

| sunny@hoclshine.com |

Product Details

Determine disinfection requirements: Firstly, determine the required sodium hypochlorite concentration and disinfection

frequency based on the size of the water body, breeding species, and local water quality standards.

2. Install sodium hypochlorite generator: Install the generator near the water source to ensure the convenience of power supply

and brine replenishment.

3. Configuration and startup equipment: Adjust the electrolysis intensity and working time of the generator according to the

set concentration. Then start the equipment and allow the sodium hypochlorite solution to flow into the water.

4. Uniform distribution: In order to ensure effective disinfection of the entire water body, it is necessary to evenly distribute

the sodium hypochlorite solution to various areas through a water pump or nozzle system.

5. Monitoring and adjustment: Use test strips or online monitoring instruments to regularly monitor the concentration of

sodium hypochlorite in water, ensuring that it remains within the effective disinfection range at all times. Adjust the generator

settings based on the detection results.

6. Safe operation: During the operation, it is necessary to comply with safety regulations, including wearing appropriate

personal protective equipment and avoiding direct contact with high concentrations of sodium hypochlorite solution.

7. Maintenance equipment: Regularly clean and maintain the sodium hypochlorite generator to maintain its optimal working

condition and extend its service life.

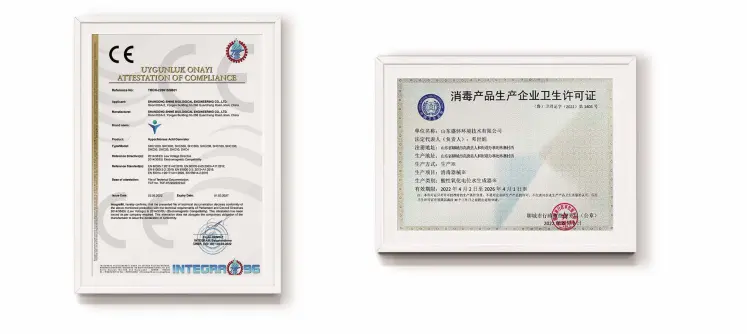

Qualification certificate

Application

Factory appearance

Customer negotiation

Submitted successfully

We will contact you as soon as possible