- HOME

- Products

- Sodium Hypochlorite Generator

- Sodium hypochlorite generator cold chain disinfection

Sodium hypochlorite generators are widely used in the food industry, beverage and other fields

Effective chlorine production: 50-15000g/H

Effective chlorine concentration: 3-10g/L

Installed power: 0.3-90KW

Host size: customized

Delivery cycle: 25 days

WhatsApp:+8619953182842

Email: henry@hoclshine.com

Product Details

In the production and processing of cold chain food, effective cleaning and disinfection systems should be developed for processing personnel, production environment, and related equipment and facilities based on the characteristics of food raw materials and products, as well as the characteristics of production and processing technology. The implementation and effectiveness of disinfection measures should be evaluated regularly. The specific disinfection targets include food production and processing personnel, raw materials and semi-finished product packaging, production and processing equipment, and the environment.

Product parameter

Effective chlorine production: 50-15000g/H

Effective chlorine concentration: 3-10g/L

Installed power: 0.3-90KW

Host size: customized

Delivery cycle: 25 days

WhatsApp:+8619953182842

Email: henry@hoclshine.com

Product advantage

-The application range of sodium hypochlorite disinfectant is wide, and there is no need for frequent switching of multiple disinfectants in production,

processing, transportation and distribution, sales and operation processes;

-Sodium hypochlorite, as a food additive or used for food processing, cleaning and disinfection, is widely used and supported by regulations in various

countries around the world.

-Instant generation of sodium hypochlorite solution through equipment, ready to use, no need for mixing, simple operation.

-Aquatic raw materials can carry foodborne pathogens. After treating the raw materials with acidic electrolytic hypochlorite water, in addition to its

disinfection effect, it can also avoid environmental pollution caused by cleaning solution and cross contamination of aquatic raw materials, reducing

the probability of microbial contamination.

-During the processing, products usually come into contact with different equipment, most of which are made of stainless steel, ceramic tiles, and glass.

Using sodium hypochlorite solution for sterilization and disinfection of utensils can prevent cross contamination between utensils and aquatic products.

Sodium hypochlorite solution has an ideal bactericidal effect on aquatic product processing equipment and has a wide range of application prospects

in aquatic product processing enterprises.

Application Display

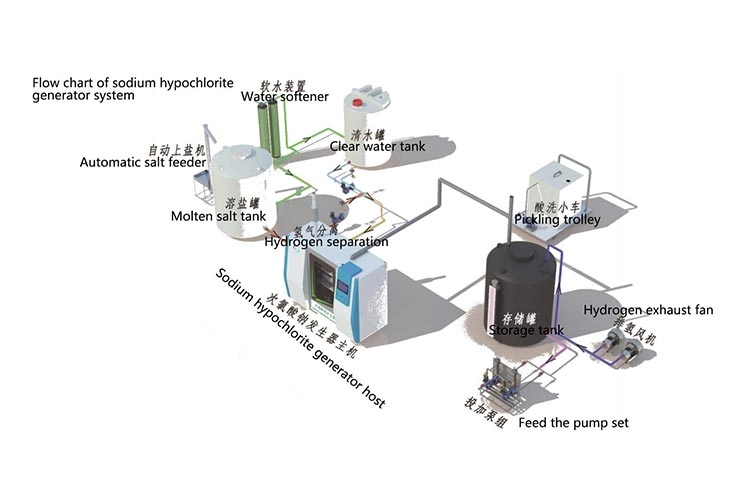

Process Flow Diagram

Customer negotiation

Qualification certificate

Submitted successfully

We will contact you as soon as possible